$3 Billion Investment for Future Generation Platform Products

SANTA CLARA, Calif., July 25, 2005 -- Intel Corporation today

announced plans to build a new 300-mm wafer fabrication facility at its

site in Chandler, Ariz. The new factory, designated Fab 32, will begin

production of leading-edge microprocessors in the second half of 2007

on 45 nanometer process technology. Construction on the $3 billion

project is set to begin immediately.

"This investment positions our manufacturing network for future

growth to support our platform initiatives and will give us additional

supply flexibility across a range of products," said Paul Otellini,

Intel CEO. "For Intel, manufacturing is a key competitive advantage

that serves as the underpinning for our business and allows us to

provide customers with leading-edge products in high volume. The

unmatched scope and scale of our investments in manufacturing help

Intel maintain industry leadership and drive innovation."

When completed, Fab 32 will become Intel's sixth 300-mm wafer

facility. The structure will be about 1 million square feet with

184,000 square feet of clean room space. The project will create up to

1000 new Intel jobs at the Arizona site over the next several years.

During the construction phase, more than 3,000 skilled trades people

will be hired to work on the project.

Intel currently operates four 300-mm fabs that provide the

equivalent manufacturing capacity of about eight 200-mm factories.

Those factories are located in Oregon, Ireland and New Mexico. The

company also has an additional 300 mm fab currently under construction

in Arizona (Fab 12) scheduled to begin operations later this year, and

one expansion in Ireland (Fab 24-2) scheduled to begin operations in

the first quarter of next year.

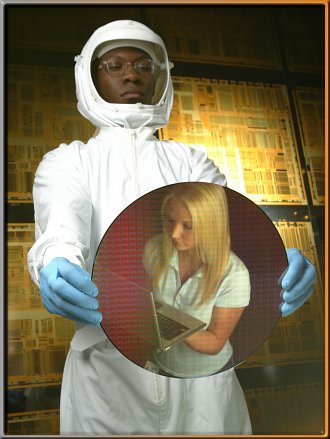

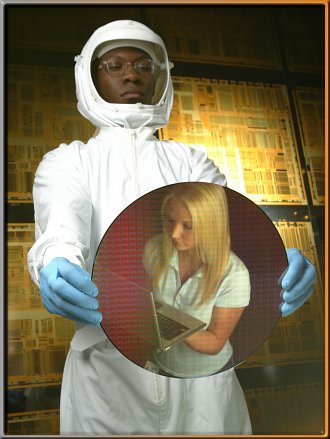

Manufacturing with 300-mm wafers (about 12 inches in diameter)

dramatically increases the ability to produce semiconductors at a lower

cost compared with more widely used 200-mm (eight-inch) wafers. The

total silicon surface area of a 300-mm wafer is 225 percent, or more

than twice that of a 200-mm wafer, and the number of printed die

(individual computer chips) is increased to 240 percent. The bigger

wafers lower the production cost per chip while diminishing overall use

of resources. Three-hundred-mm wafer manufacturing will use 40 percent

less energy and water per chip than a 200-mm wafer factory.

Separately, Intel said it will invest $105 million dollars to

convert an existing inactive wafer fab in New Mexico to a component

temporary test facility. The project will provide additional test

capacity to the company's factory network for the next two years and

will result in an additional 300 jobs at the New Mexico site during

that period.

News Source: Intel Press Release

Links